Disperser blades are mixing tool used in industrial processes for the dispersion, blending, and homogenization of materials. Disperser blades come in various shapes and sizes, each designed for specific mixing requirements. Here we introduce 7 types of disperser blades!

Rugged, efficient design with high shear with pumping action. Great for paint dispersion. Also used in clay processing, paper coatings, ink manufacturing, and many other applications.

High pumping action. Use minimal shear and heat buildup to mix the entire batch. Great for mixing and letdown of coatings.

Provide a combination of high shear along with excellent batch movement. Uses in high-viscosity and high-solids materials.

The aggressive tooth design disperser blade works well on ceramics and difficult to de-agglomerate materials.

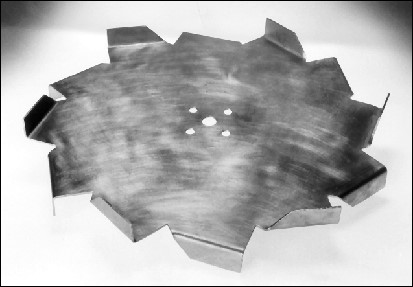

Perfect for cutting in or shredding rubber, wax, and other soft materials that tend to "gum up" on standard impellers.

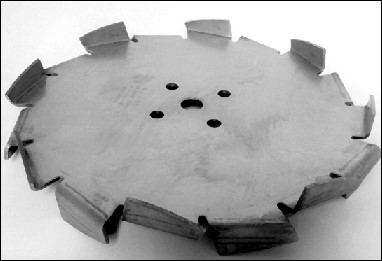

One popular disperser blade for high-speed dispersion applications, with a rectangle style tooth pattern.

Utilized for high-speed blending and agitation where a medium amount of shear is required.