JCT Machinery is a reputable manufacturer known for its high-quality industrial equipment, including the Sigma Blade Mixer. A sigma blade mixer, also known as a double-arm mixer or kneader, is a type of mixing equipment commonly used in the chemical, pharmaceutical, and food processing industries. It is designed to knead, mix, and blend high-viscosity materials, pastes, doughs, and other cohesive substances.

SEND INQUIRY NOW

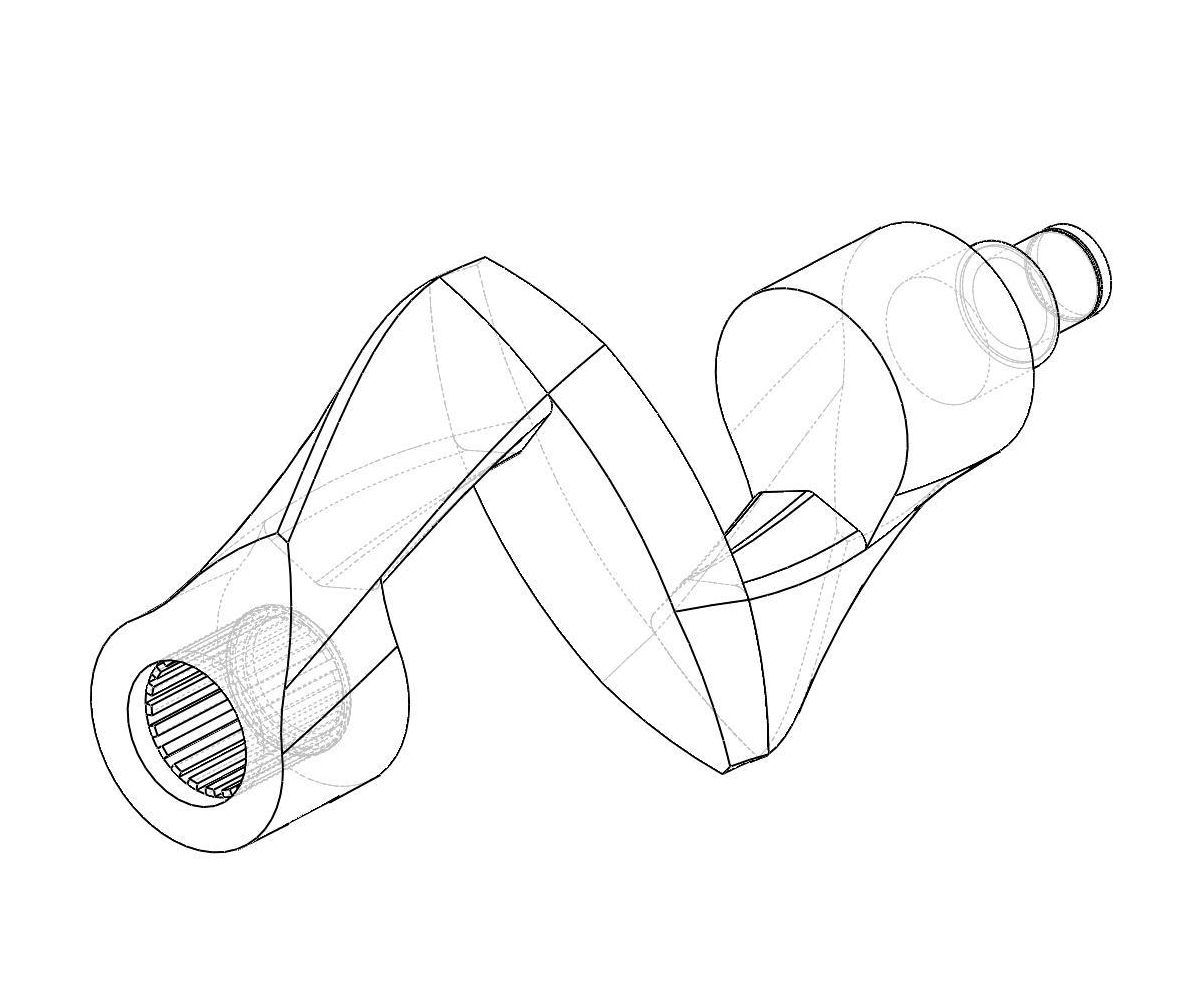

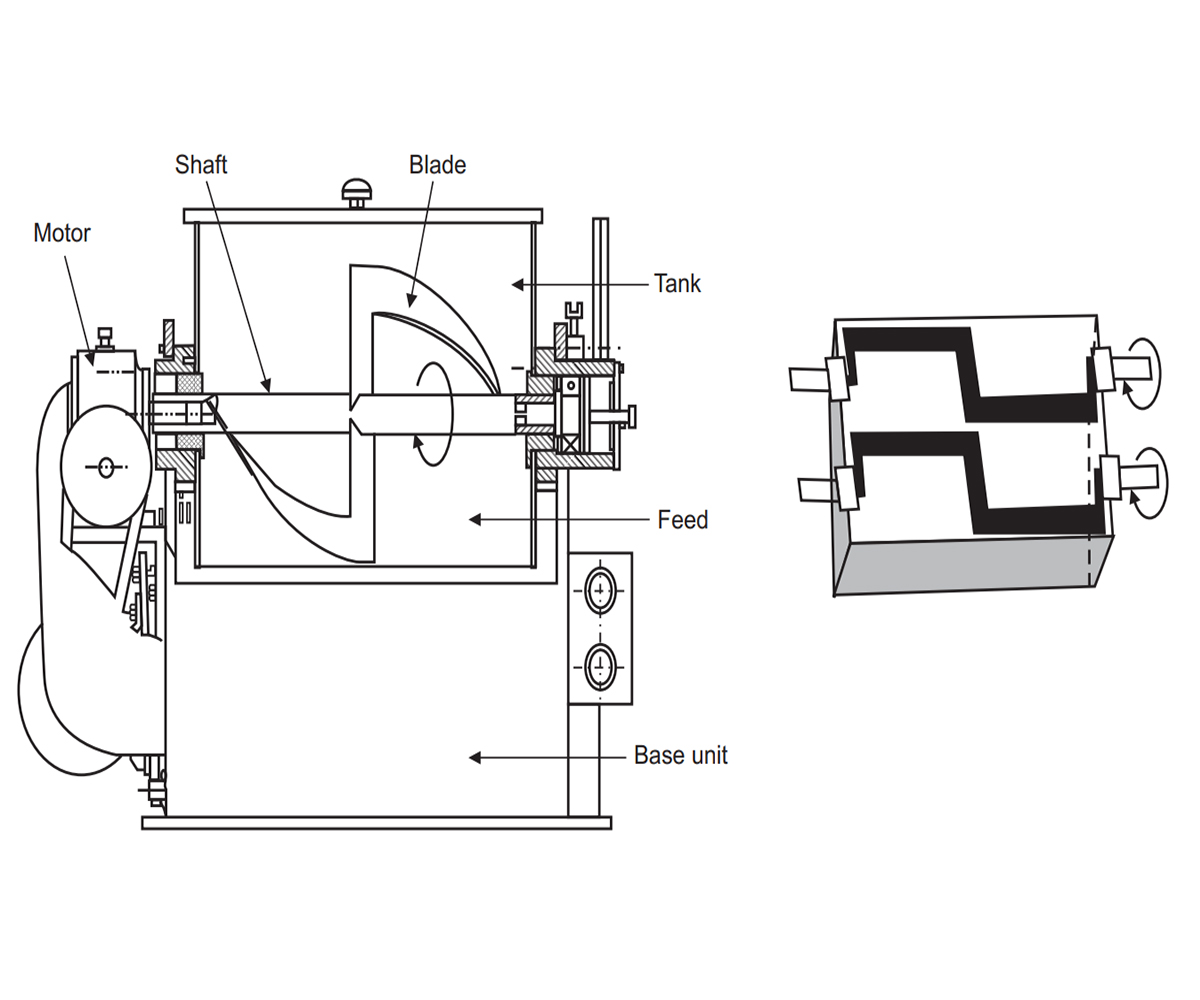

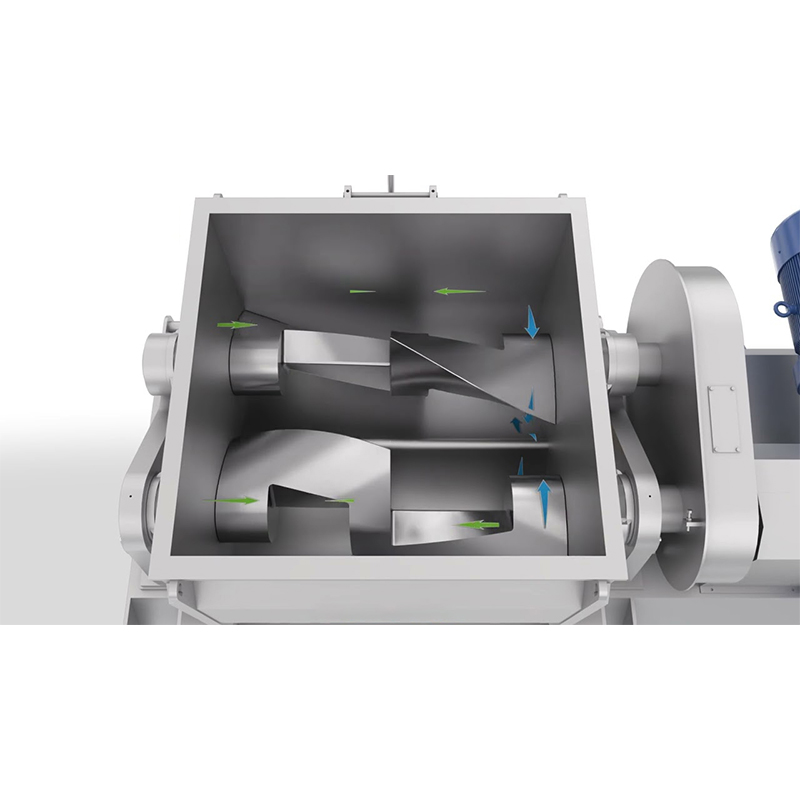

The sigma blade mixer consists of two blades, typically in the shape of an "S" or sigma, that are mounted on parallel shafts and rotate in opposite directions. The blades are usually curved or tilted to form a trough-shaped mixing chamber. The rotation of the sigma blades generates a shearing action, causing the material to be kneaded, folded, and mixed thoroughly.

Sigma blade mixers offer efficient and thorough mixing capabilities, especially for high-viscosity and cohesive materials. They ensure uniform distribution of ingredients, enhance product consistency, and facilitate the development of desired product characteristics in a wide range of industries.

Features:

· Blade Design

· Mixing Principle

· High Viscosity Mixing

· Efficient Heat Transfer

· Batch Operation

| Type | SBM-5 | SBM-10 | SBM-100 | SBM-300 | SBM-500 | SBM-1000 | SBM-1500 | SBM-2000 | SBM-3000 | SBM-4000 | SBM-5000 | |

| Volume (L) | 5 | 10 | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | |

| Rotation Speed (Rpm) | 3323 | 3323 | 3522 | 3721 | 3721 | 3525 | 3016 | 3016 | 3827 | 3827 | 3827 | |

| Main Motor Power (Kw) | 0.75 | 101 | 3-75 | 11-30 | 15-37 | 22-90 | 22-90 | 30-100 | 30-110 | 45-110 | 55-132 | |

Heating Methods | Steam Pressure(Mpa) | 0.3 | ||||||||||

Electric Power(Kw) | 1 | 1 | 4 | 9 | 16.2 | 27 | 32.4 | 40 | 72 | 72 | 96 | |

| Vacuum (Mpa) | -0.094 (acuum Kneader) | |||||||||||

| Pressure (Mpa) | 0.45 (Pressure Kneader) | 0.35 (Pressure Kneader) | 0.30 (Pressure Kneader) | |||||||||

| Weight (Kg) | 300 | 400 | 1250 | 1600 | 3000 | 4500 | 5800 | 6500 | 11000 | 13000 | 21000 | |

JCT Machinery was established in 2006 at Foshan China that specializes in design, manufacture, and supply of various industrial machinery and equipment, such as sigma blade mixer.

JCT Machinery has developed and designed cases with multiple partners around the world, focusing on providing reliable and efficient equipment for industrial processes.

◪ Over 17 years experience

◪ Drawings issued within 3 days

◪ Completed within 30 days at the earliest

◪ Chief design engineer graduated from Tsinghua University

◪ JCT Machinery Sigma Mixer has UDEM certificate